|

| Connecting flights should be easy. This was inexcusable. |

What began as a routine pre-flight process (July 22 2024) quickly unraveled into unexpected challenges that only hinted at the struggles to come when checking in for our flight from the UK to the US. Completing the online check-in initially seemed straightforward, having meticulously filled out our flier profiles with our known traveler, passport and phone numbers as well as addresses and birth dates. We then encountered an error message instructing us to visit a customer service agent at the airport. This inconvenience meant allotting an additional thirty minutes to navigate this unexpected hurdle, as we prepared to have our passports scrutinized and boarding passes printed in person.

|

| Errors with the app, different errors on the website, no real customer service to be found. |

We got to the Manchester airport with lots of time to spare and I did not see a customer service ticket counter anywhere. We asked a British Airways employee and they directed us over to the bag check queue area. There were three lines queued up with at least 70 people already in line. Two agents behind the counter, moving at a glacial pace. The self-service kiosks were all out of order (likely to the CrowdStrike Microsoft meltdown three days prior). This wasn't looking good. We got in a queue and I was watching the two agents behind the counter, hoping that one would call their supervisor and ask for help. What I saw instead was someone who was on the upper deck of the bag check area preparing to leave (to go on break?). I got out of line to ask her how I could simply get a boarding pass printed, I did not need to check a bag at all. She wasn't helpful and said she didn't do check ins and I'd have to wait in the queue. Just then another employee came up to her and was commenting the people in the queue lines were all in the wrong place and that this line was for this and the other line was for that. I explained to her that I simply needed a boarding pass printed, my passport verified and which line should I be in for that? She said the middle line was for bag drop only which didn't answer my question. We moved our things over into the middle queue and I began to make a message for my phone screen where I could communicate to anyone within my line of sight that I only needed a boarding pass, not to check a bag. The other people in line were getting anxious and angry as the line wasn't moving at all and people were getting frustrated. I wanted a quick way to communicate that I was not checking a bag and only needed a boarding pass printed which was a quick process. I wanted to avoid incurring the ire of the increasingly disgruntled people waiting to check their luggage.

I kept watch over the business and first-class lines to my left as they seemed to be moving a tiny bit. I spied a British Airways flight attendant in line and my guess was she didn't need to check a bag either. I got her attention and showed her my phone screen message that I just needed a boarding pass printed. She read it and nodded her head in understanding and I approached her and got in line behind her, next up in line. I had both of our passports and flight record indicator numbers in hand, and David waiting in the original queue spot in case we needed to go back to where we started. The gate agent checked our passports and printed our boarding passes for MAN>LHR, LHR>PHL, PHL>TPA and then we were off to our gate.

If you haven't traveled through airports in the UK, you may not know that there are multiple places where you stand within the foot outlines on the floor by the glass-doored turnstile and your picture is taken to verify your boarding pass and your passport. There are turnstile gates at the entrance to screening security where you have to scan your passport, boarding pass and then look into the camera at the turnstile to have your picture taken to compare to your passport. These turnstiles are also present at the ingress point for each gate area. David had issues with the facial recognition camera at the ingress point to our Manchester flight gate (which hadn't happened at the security screening turnstile). The British Airways employee stationed at the flight gate turnstiles asked for David's passport and brought his first photo up on her monitor to compare it to the one he'd just taken at the flight gate. She remarked that they looked exactly the same and wondered why the system was rejecting his ingress gate photo. She scanned his passport barcode and sent us on our way to wait in line to board our flight to LHR.

Our flight to LHR was delayed a bit (unknown reasons) but the pilot came over the intercom and said he'd be able to make up some of that time while we were in the air. The flight records show we landed at 13:01 pm and disembarked the plane and followed the purple Flight Connections signs to the next bank of facial recognition/boarding pass scanning turnstiles. We reached the bank of turnstiles at 13:10, and each of us put the boarding pass for our connecting flight on the scanner, looked into the camera at the turnstile, and were both shown the message "See a Customer Service Agent," and the turnstiles did not open. The flight from MAN was a full flight and a majority of the passengers were queuing up at these turnstiles. Some were getting through, but lots were not. The man sitting at a desk to the left of these turnstiles seemed unconcerned about the growing crowd of passengers who could not pass these turnstiles to get to their connecting flights. We had forty minutes to get to our gate in the same terminal which should be ample time. We asked this man what we should do and what was the problem. His response was to get in the customer service line and ask the British Airways people. The reasoning he gave was that we must've left some information out of our flight profile that needed to be added in. My husband was quite angry (as was I) and said this was not possible as we'd just gotten off a flight and had our boarding passes in hand. If there was missing information we wouldn't have been cleared for the flight we just got off of. This employee didn't care and said just get in the queue, I don't work for British Airways and then proceeded to call security to come and chastise my husband for being angry and getting loud.

Watching and listening to the people around me, I learned that the people at the front of the line for customer service had been waiting for nearly two hours. There were only two British Airways Customer Service employees staffing the counter for a queue of nearly 80 passengers. Standing where we were in line, it looked like it would take us at least that long, if not longer, to reach the customer service desk. The crowd of passengers who could not clear the turnstiles was growing exponentially. Families traveling together had gotten split apart. The wife on the cleared side looking at her husband and child on the other side of the turnstile and wondering if they were going to get help in time to make their flight, another couple where the wife passed through the turnstile but the husband was on the other side of it. Looking at the time tick by, I was watching our window of opportunity to catch our connecting flight close without anyone from British Airways giving a damn.

Dozens of British Airways employees were coming and going through the larger glass turnstile doors. It looked like some sort of major shift change was taking place. Perhaps a lunch break? I cannot say. I saw at least a dozen ramp agents in their high-vis vests come and go. Management types came out and stood around with their arms crossed, giving made-up reasons or excuses for why we should all just keep waiting in line. They began to explain that our flight had landed late and that we were being held because we wouldn't have made the connection anyway, which is a complete falsehood. I saw at least another dozen British Airways employees in customer service uniforms come and go, looking askance at the queue which had now grown to at least 70 people long. None of the management types were taking ownership of the situation. They were just there offering no assistance, making excuses, and giving their opinions on why we all had to just wait in the queue. It was clear to me that this was not related to the CrowdStrike outage that hit a few days prior. Some people cleared the turnstiles, others had to try a couple of times (getting their picture taken by the turnstile) and then were admitted through. Against the backdrop of the worldwide computer meltdown that had snarled flights globally, we knew that if we missed this flight we’d be thrown into the maelstrom of stranded passengers for days as a result.

Our connecting flight left without us, and we had no choice but to resign ourselves to this purgatorial queue because where else could we actually go? One of the British Airways employees told everyone in the queue to keep refreshing their booking in the British Airways app because the system would rebook them on another flight automatically. The two Customer Service agents became five Customer Service agents, and still, the line was not moving.

My husband made a few attempts at calling British Airways representatives, but their automated calling system would only offer that “call waits are currently long,” and then it would hang up on him. The British Airways Customer Service agents were helping us through phone calls to other British Airways employees located somewhere else. The British Airways Customer Service reps in front of us were put on hold, their calls got disconnected and the line was still growing. The process of rebooking passengers was incredibly slow, a family of four took nearly twenty minutes to get their flights rebooked and tickets printed.

I overheard a British Airways employee say that the system running the scanning turnstiles had “timed out its password,” and it could've been a simple fix, and us missing our flight could have been avoided, but by that time, it was too late for us. I had suspicions that this was related to an inaccurate facial recognition system that when pictures with different lighting and shadow angles (as I'd seen in David's pictures from that morning) simply denied the passenger access rather than presenting them with an error message that was actionable or even meaningful.

The line for help barely moved. I watched the time crawl. Two hours passed and the families that were split by the ingress turnstiles were no longer there. Someone helped them make their connecting flight but did nothing to alleviate the enormous line of passengers who were denied access to their connecting flights and were now stranded. Three hours passed and I still had nearly thirty people in front of me in line. A British Airways Customer Service representative brought out a stack of printed hotel vouchers to those of us standing in line who had missed our connecting flights. The only suggestion she had was to watch the app for a rebooking. She recommended leaving the queue and the airport, going to the hotel, and letting the app rebook us automatically. Some people gave up and left after having waited in line for over three hours. Other people said they didn't trust the app to rebook them and they were not going to leave until they had a new flight booked with the British Airways Customer Service reps at the counter. I took a hotel voucher and kept my place in line.

Three hours had gone past. I'd watched as one Customer Service agent was visibly upset at the massive crowd of passengers waiting for help. She was asking her co-workers if she could include them in the email she was writing to her supervisors about how badly the airline had handled this situation, causing people to miss their connecting flights and wait in line for hours upon hours. I hoped I'd get her as our Customer Service agent when we got to the counter. She seemed to care a little about our collective plight. Another Customer Service agent appeared on the scene, stationed at the small podium by the glass turnstiles, and began asking the crowd if anyone had a connecting flight and simply needed our documents scanned. I asked her where she was about four hours ago as, at this point, everyone in line had already missed their fight, and she was of no use to us now. There was a constant influx of new passengers arriving at the ingress turnstiles she could help while those refused access earlier by the turnstiles could only continue to wait in line.

While I was waiting in line, I'd researched my flight options home and made note of flight numbers, days, and times in hopes of making our rebooking quicker. By the time we reached the British Airways Customer Service counter, we had been waiting in line for nearly four and a half hours. The Customer Service Representative thanked me for that and we found a flight leaving out the next morning from LHR, connecting through ORD before landing in TPA late the next evening. We asked him to level with us and tell us what the actual problem had been to cause us to miss our connection and have to wait in line for help for over four hours. He said it really came down to gross mismanagement by British Airways employees. He said that if someone had been stationed at the kiosk desk by the ingress turnstiles, they would have seen what the real issue was with each passenger who was refused access by the turnstile system and been able to scan the barcode on the passenger's passport (with the slide through scanner built into the top of their keyboards) - everyone would have gotten to their next flights without much of a slowdown.

By the time we boarded the hotel shuttle bus and arrived at the hotel, it was after 6 p.m. We received instructions for where to go to have our hot meal.

This inexcusable malfeasance caused us to miss our flight, wait in line for over four hours for assistance, and spend another full day traveling home due to an outrageous lack of staffing, complete absence of customer service, or anyone from the airline caring about what our customer experience was like or had been. What is my recourse as a passenger? How can I never be in this situation again? Should I have been louder, more angry, shouting to no one in particular for help for fear of an employee feeling like they were being abused and calling security to suppress my vitriol? Should I have tried to jump the turnstile and run to the gate and state my predicament to the next gate agent in hopes they'd care and help? Should I have pretended to not understand that the turnstile was rejecting my access and walked through behind another passenger who was cleared access? I can't say if any of these imagined scenarios would have a better outcome than what we were subject to.

One foolproof way I can avoid this type of gross negligence is to never fly British Airways ever again and to never connect through London's Heathrow Airport ever again. I refuse to be subjected to this kind of treatment and have no recourse available regarding the complete waste of two days of my life for no legitimate reason.

Who should I complain to at British Airways? Would they care? What sort of recompense could I receive that would possibly make up for the mental and emotional anguish of being enraged for five hours at the stupidity of being prevented from boarding our connecting flight and being forced to wait nearly five hours to get assistance? This is, of course, a rhetorical question: British Airways is a joyless, soulless corporate behemoth that lacks the capacity to self-correct or acknowledge inefficiencies; I’m sure those redundant turnstiles are still there, denying passengers access to their connecting flights and costing British Airways immeasurable amounts of fiscal damages every day.

|

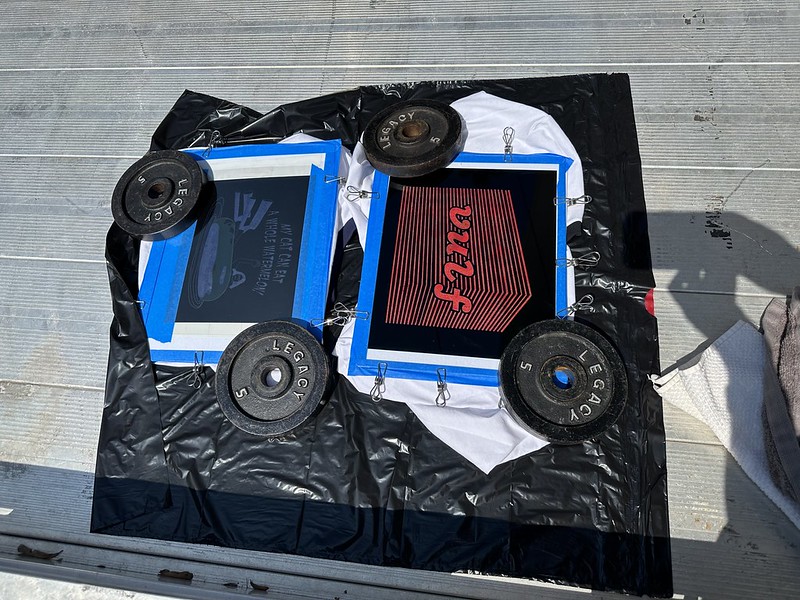

| All the people in this photo were affected by British Airways' gross negligence. I call this the "Trapped in Purgatory Dinner Gathering." |